About Finsulate Antifouling

Finsulate is a typical Dutch maritime invention and has been applied to yachts and vessels on every continent. Ranging from small sloops and day sailers up to offshore support vessels and dry weight bulkers. The Finsulate concept works in any environment and is up to any challenge!

Direct to

The Finsulate Concept

Without antifouling, any surface in water, like ship hulls and offshore constructions, will foul with algae, mussels and barnacles.

Traditional antifouling paints are highly toxic and very harmful to the environment. Finsulate offers an environmental friendly solution to the fouling challenge.

Inspiration for Finsulate

Nature is a source of technological developments in many cases. For Finsulate, the spines of the Sea Urchin were the inspiration. Rik Breur was elected European Inventor of the Year 2019 with this concept.

Curious to learn about the options for your yacht?

Finsulate reviews and experiences

Independent research shows the effectiveness of Finsulate

Every year, yachts are painted again and again. Besides the biocides, where does the paint go? Exactly into our precious oceans!

That has to change, but what are the alternatives? Milieucentraal has investigated the alternatives.

Finsulate lifespan

What is the realistic lifetime of Finsulate? We warrant 5 years, yet in practice we already show longer lifespans are possible. One of the first boats that we applied Finsulate to, is sailing in the Zaanstreek (NL). Meanwhile, Robbert has enjoyed Finsulate for 7 years (since 2014). In case the film needs tob e replaced, it is possible with a steam cleaner or with hot air. Once the old film is removed, Finsulate can directly be renewed.

Cleaning Finsulate

The Finsulate surface consists of very fine fibers. The fibers are so close together that organisms cannot get in between. As nature is strong, fouling can occur eventually on top of the fibers. This fouling is easily cleaned off.

This Dehler sailboat is high pressure washed before winter storage.

Five years sailing with Finsulate

Applying antifouling paint with mouth cap, a bloom of toxic paint when you want to remove some fouling in the water, this must change! For many boat owners the environment is a large factor when selecting Finsulate. The additional benefit of the longevity is a second strong argument. At least 5 years of no sanding and painting, we talked to mr. De Vries about his experiences.

Finsulate experience with “drying out”

The Finsulate film is stronger than you might think. Lifting and resting on stands are no problem. And if a damage occurs, you can easily repair by yourself. In case of drying out, sharp objects can of course damage the film like it would with regular paint. Ineke Dicker dries out regularly in the Wadden Sea. After the sailing season they make a small repair job on the hull.

User Experiences

Aangebracht in: March 2018

"We had two of our charter yachts provided with Finsulate. Being a comparatively new product in the yachting market back then, in the beginning there were some minor issues. These were well resolved by the Finsulate team though. Now it's been 3 years and we are still happy with it. I also would like to add that we were positively surprised not to see any major on-growth on the yachts! "

Aangebracht in: March 2017

"in 2020, after 3 years with Finsulate, we took Sofia out of the water for maintenance works. And at that occasion we also inspected the Finsulate on her hull. Turned out there were some minor repairs required, due to mechanical damages. All of these were swiftly done by the Finsulate team. Meanwhile, Sloepvrienden is already cruising since 4 years with Finsulate and we are really satisfied with the product."

Aangebracht in: September 2017

"I was used to clean our houseboat on a monthly basis and take it out once per year. Now with Finsulate my home is in the water for 3 consecutive years already. And the cleaning stays as easy as in the beginning. Super happy since I don’t need to get my house craned out of the water each year any more! "

Aangebracht in: March 2020

"We have finished our first year with Finsulate. We liked it very much. No problems with adhesion even when drying out. That is why we also covered the last part of the keel this year."

Aangebracht in: May 2019

"I really enjoyed this innovative antifouling product this year. We didn't have any significant fouling. Just some slime which is easy to remove. While many mussels grew quickly in the unprotected areas of the hull. An additional proof of the strong antifouling properties! I'm very happy that I chose your product. No maintenance in the winter any more!"

Aangebracht in: January 2015

"The application is easy and clean; two experienced wrappers finished the job in a day. In displacement mode (95% of the time) I enjoy the same performance compared to traditional anti-fouling. In planing mode it’s a few % lower. There has been no fouling after the season and no need for re-application, saving me significant maintenance costs while protecting our children’s planet. For me Finsulate stands for environmental friendly, lower maintenance costs while maintaining relevant performance. "

Finsulate Do-It-Yourself installation?

Finsulate is only applied by certified installers. It does not seem difficult, yet it requires practical experience and skills. The certified installation also enables us to warrant Finsulate for 5 years.

Application of Finsulate

The adventurers of Seawind Adventure are committed to their environment and chose an environmental friendly alternative for the traditional toxic antifouling paint. This vide shows a time lapse of the installation.

Request a quotation

Finsulate in the news

The Hiswa Product of the Year election in 2018 and the European Inventor of the Year election in 2019 have been triggers for international media and TV. Also in The Netherlands, several media have picked up the innovation of Finsulate.

Finsulate at Discovery Channel

Discovery Channel is looking for special companies and inventions in the series “how do they do it?” In February 2021, presenter Tim Senders came to visit to learn more about this sustainable alternative to antifouling paints. On the former barge ‘De Pelikaan in Amsterdam’, the presenter immediately lent a hand with the application of Finsulate on a small sloop and asked us the question: how do they do it?

Finsulate bij het Ei van Midas

Het product van het jaar op de Hiswa in 2018 en de Europese uitvindersprijs zijn onder andere de aanleiding voor een item bij buitenlandse TV stations maar ook bij onze eigen Midas en Hart van Nederland. Rik Breur legt het graag uit hoe Finsulate werkt, en blijft dat doen zolang er nog verf met biociden en metalen in het vaarwater terecht komen.

Finsulate at 'Hart van Nederland'

In 2019 Finsulate inventor Rik Breur won the prestigious European Inventor Award, issued by the European Patent Office. More than 100 news items were issued in the media. Also TV-station SBS6 broadcasted an item on their news show.

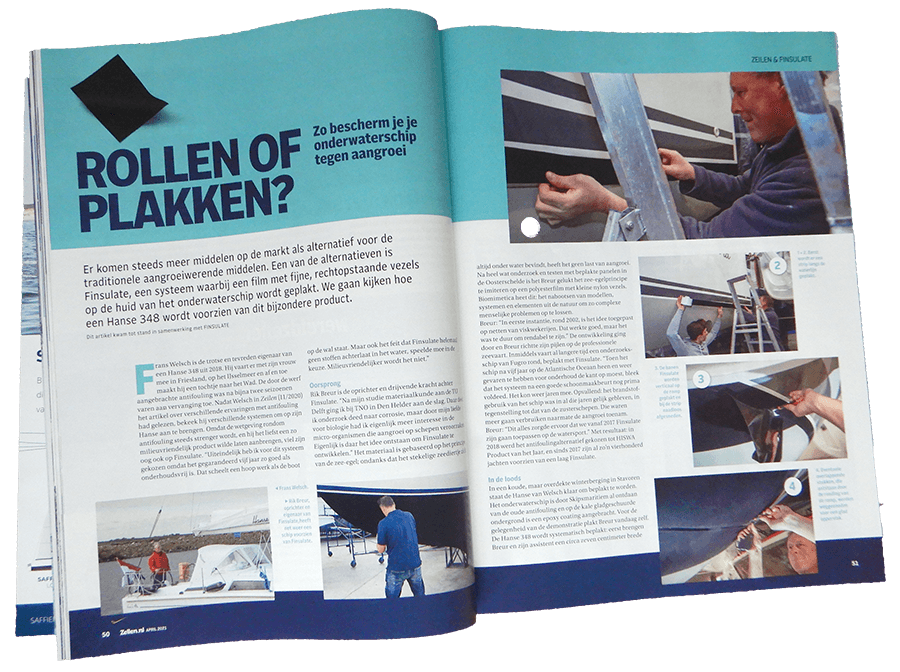

Finsulate in Zeilen Magazine

Many sailors follow the newest developments in the sailing business through the Dutch magazine Zeilen. Also the search for alternatives for antifouling paint starts here Zeilen wrote an extensive article about the Finsulate technology including some interesting user-references.